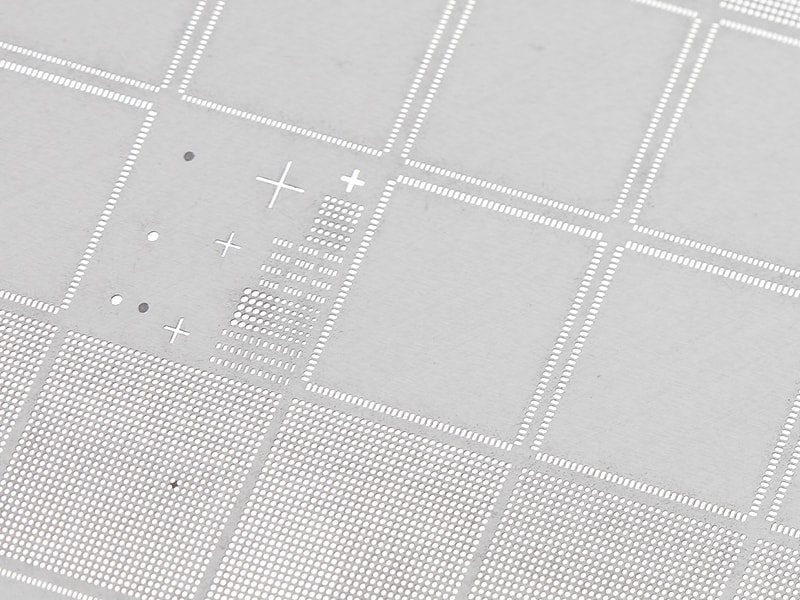

Laser-cut precision stencils such as SMD stencils are the standard for the precise application of solder and printing pastes, adhesives and other materials to rigid or flexible printed circuit boards as well as to surfaces such as silicon wafers (wafer bumping), glass or ceramic substrates (LTCC). These stencils enable precise placement and volume definition, which is crucial for the subsequent automated assembly of electronic components such as microchips, SMD components, contact elements and other semiconductor components. This technology is also used in flip-chip assembly.

Our precision stencils are available in all standard formats and for all quick-release frames. For particularly demanding applications, we also offer electropolishing in combination with nanocoating to further improve the performance and durability of the stencils.

Advantages of our precision stencils:

- Highest precision: laser-cut stencils guarantee exact material application.

- Versatility: Suitable for rigid and flexible PCBs and various substrates.

- Automated assembly: Perfect preparation for the placement and fusion of electronic components.

- Advanced options: Electropolishing and nanocoating for demanding applications.

Opt for precision templates from KMLT® and benefit from our expertise and advanced technologies in laser cutting technology.