Our special machines are perfect for manufacturing precision parts from almost all metals, precious metals and alloys in material thicknesses from 0.005 mm to 3.0 mm. We offer various processes for different accuracy ranges:

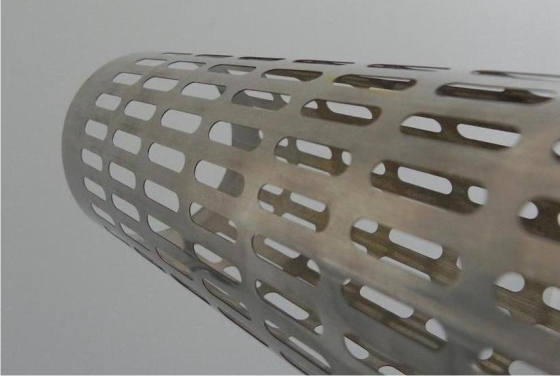

Laser cutting

Ideal for cutting metals with high precision and speed. This process is particularly suitable for thicker materials (up to around 3 mm in our case) and larger components.

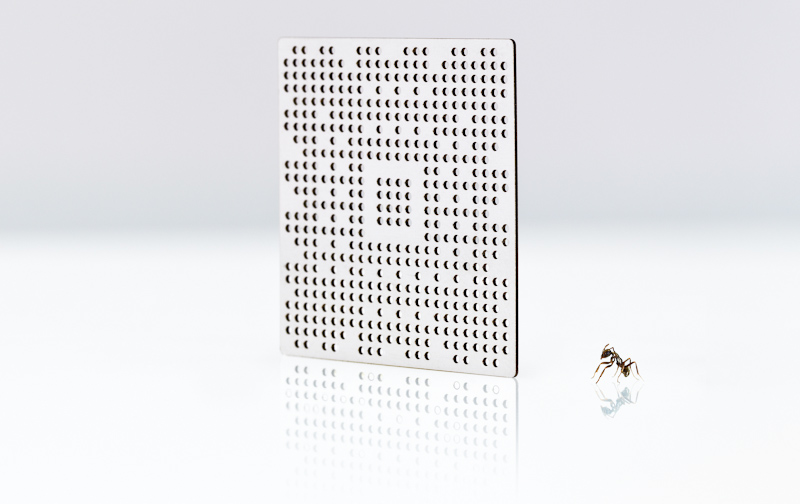

Laser fine cutting

This technique enables the cutting of very thin materials with the highest accuracy. It is perfect for applications that require minimal burr formation and the finest details, for example for precision stencils or masks.

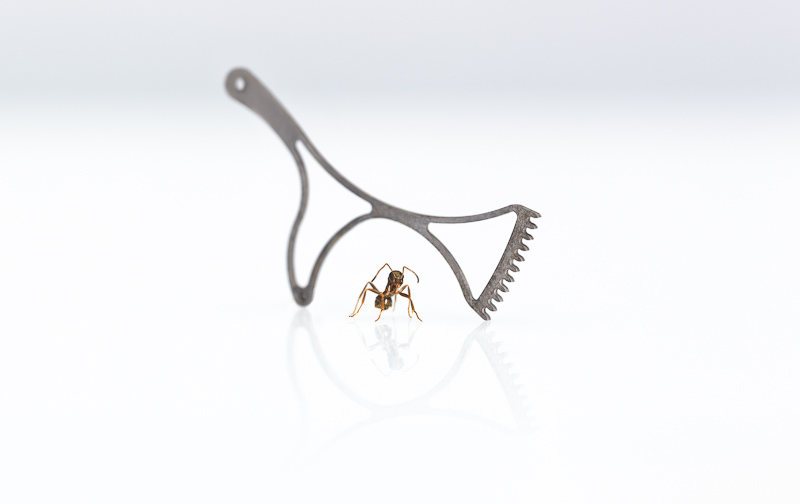

Laser micro cutting

Specially developed for processing micro components, this method offers extremely precise, virtually burr-free cuts with reduced temperature input and minimal material deformation. The machines for this have a hard stone/granite structure and are equipped with highly dynamic, air-bearing drive systems.

This process is ideal for the production of miniature components in the watch industry, microelectronics and medical technology.Our strengths

Highest precision: Manufacturing tolerances of up to ±3 µm, depending on part geometry and material properties, verifiable through detailed measurement reports.

Versatile material processing: Processing of a wide range of materials, including metals, precious metals and alloys.

Industry solutions

Our laser technology is used in many different industries:

- Microelectronics and electronics

- Optics and precision engineering

- medical technology

- Watchmaking and luxury goods industry

- Precision mechanical engineering

- Automotive industry

- Aerospace industry

- Research and development

Product diversity

We produce a wide range of precision parts, both as individual parts and in large series:

- Mechanical watch parts

- Spring elements

- Shielding plates

- Calibration masks

- Register rings

- Gobos

- Shims

- Laser precision parts of all kinds