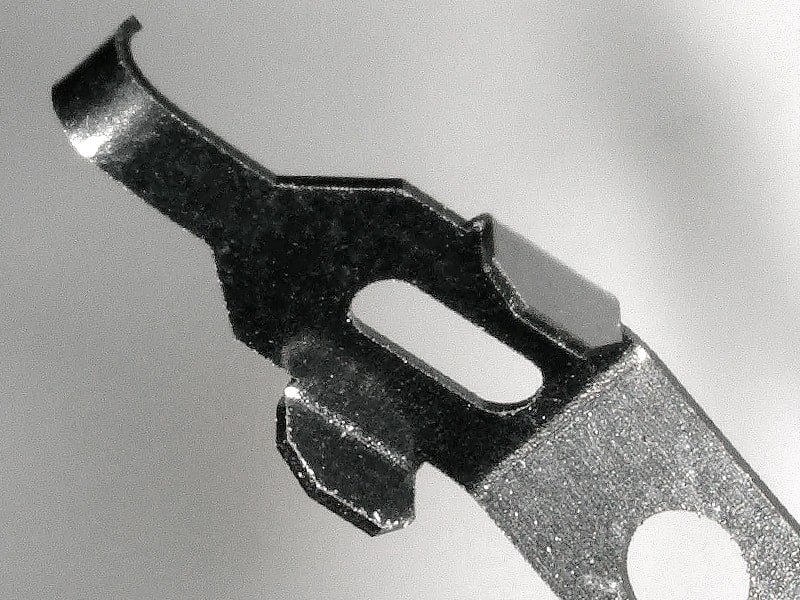

The cutouts can be bent into final shapes within the specified dimensions using our swivel bending machine for small parts.

Miniature housings, ESD housings, shielding, contact plates, flat form springs: Our range of services is ideal for small and medium batch sizes in particular.

Applications for these services are typically found in the fields of electronics/electrical engineering and precision engineering.

Additional services

Microbending

| Max. bending width: | 150 mm |

| Max. Sheet thickness at 150 mm: | 1.0 mm |

| For smaller bending width max.: | 2.0 mm |

| Available radii: | 0.2 mm / 0.5 mm / 1.0 mm / 2.0 mm |

| Accuracy: | 0.1 mm / 0.5° |

Micropolishing

KMLT® has a modern satellite centrifugal force system for surface optimization of small and micro parts.

The multi-stage process allows for targeted and customer-specific adjustments to achieve desired qualities.

Challenging tolerances in the single-digit micrometer range are maintained, edges are broken and appealing surface qualities are achieved. This process is used in particular for watch parts or medical technology parts.

To achieve perfect results, individual process formulations are created for each new product.

| Min. part size: | approx. 1.0 mm x 1.0 mm x 0.1 mm |

| Max. part size: | approx. 40 mm x 40 mm x 1.0 mm |

| Max. process part quantity: | depending on part size |

| Standard process: | deburring / rounding |

| Multi-stage process: | deburring, fine grinding, polishing |

| Creation of formulation: | individually within 14 working days |

Electropolishing

KMLT® also recommends electropolishing for surface optimization, especially for sophisticated SMD stencils.

Electropolishing on this system is also ideal for flat, small and very small components that need to be continuous in the sheet as a panel.

Under the influence of DC and electrolyte, tips and edges in particular are smoothed. This results in a leveling of the micro-roughness and the finest deburring. The passivity and corrosion resistance are retained.

| Min. sheet size: | approx. 150.0 mm x 20.0 mm x 0.08 mm |

| Max. sheet size: | approx. 1000 mm x 600 mm x 1.0 mm |

| Max. process part quantity: | depending on part size |

| Standard process: | electrochemical deburring |

| Material: | stainless steel / ferritic and austenitic CrNi steel and CrNiMo steel |

| Electrolyte: | E268 |

Glass bead blasting

Glass bead blasting is suitable for gentle cleaning and deburring of surfaces.

In a closed blasting cabinet, precisely defined grain sizes starting from 150 µm are dry-blasted onto the surface of the workpiece using compressed air.

All adhering particles such as scale or rust are removed from the surface during this process.

| Min. part size: | approx. 50.0 mm x 20.0 mm x 0.5 mm |

| Max. part size: | approx. 600 mm x 300 mm x 200 mm |

| Max. process part quantity: | depending on part size |

| Standard process: | deburring / matting |

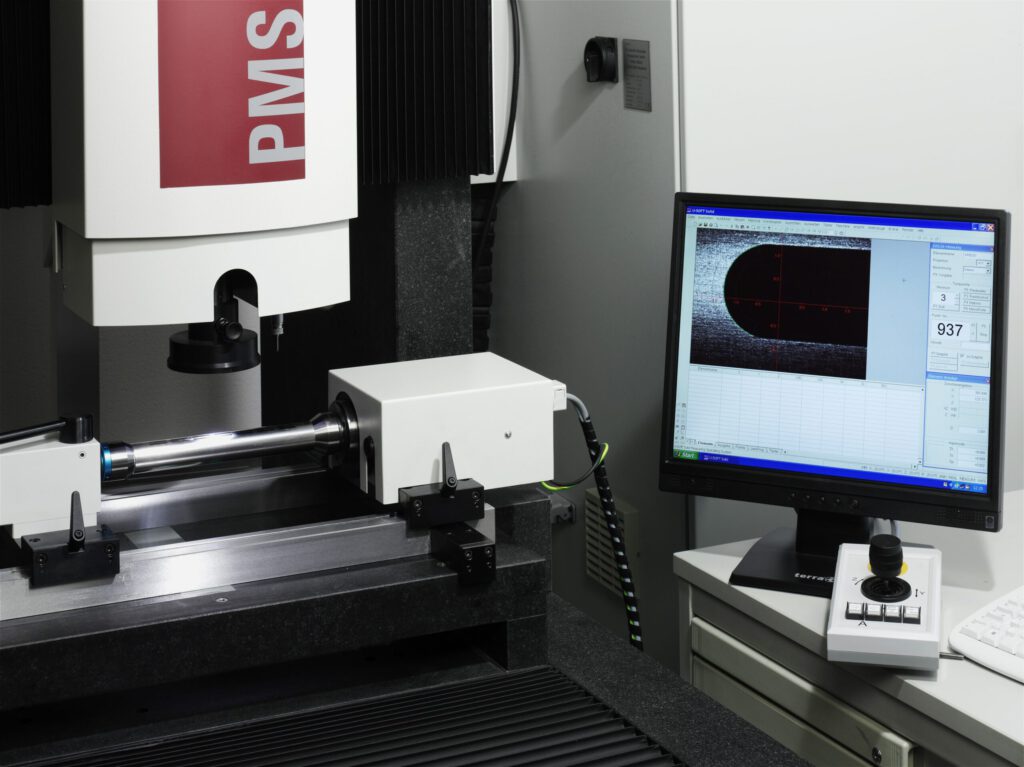

Contract measurement of customer parts

Portal measuring machines from Dr. Heinrich Schneider Messtechnik GmbH as well as several digital microscopes and digital measuring projectors from Keyence are used for internal quality control.

In addition, an LPKF scanning system is available for stencils and sheet metal parts.

With these systems, we are capable of creating cross-sectional profiles with up to 1000x magnification, including evaluation of heights, widths, angles, radii, and more.

Measurement of customer parts on all systems is available as a contract service.

For parts without available manufacturing documents, new CAD data can be generated.