In addition to machine brushing or vibratory finishing, KMLT® offers an extensive range of further processing options for your parts after laser processing. Our customized processing steps are individually tailored to your requirements in order to always achieve the best overall results.

Microbending

KMLT® - Perfect further machining after laser processing

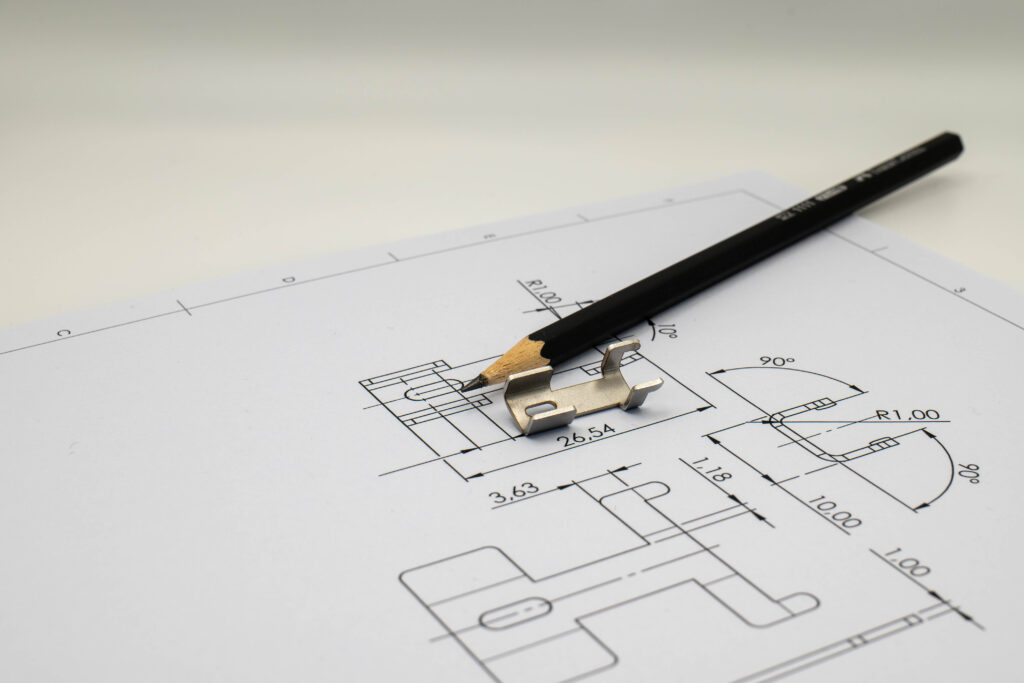

Precise bending for customized cuts

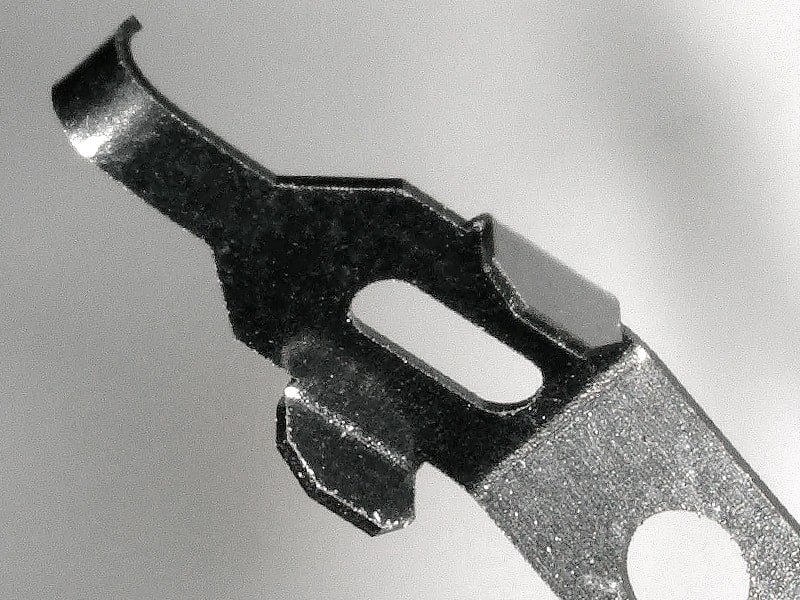

Our state-of-the-art swivel-bending technology makes it possible to precisely bend filigree blanks in particular into final shapes. We offer optimum solutions, particularly for small and medium-sized batches.

Applications

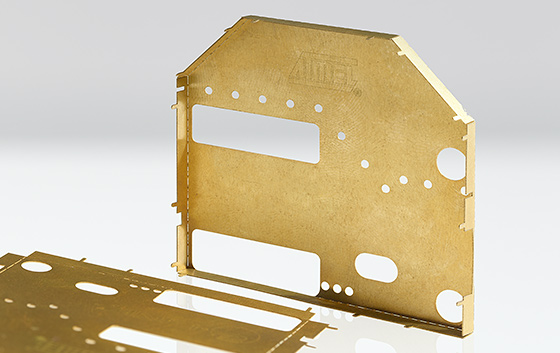

- Miniature enclosures

- ESD enclosures

- Shields

- Contact plates

- Flat form springs

Mikrobiegen von KMLT®

The components processed by us in this way are mainly used in the fields of electronics, electrical engineering, medical technology, device construction, precision mechanics and precision engineering. Benefit from our expertise and state-of-the-art technology for your specific requirements.

Technical details on microbending

| Max. bending width: | 150 mm |

| Max. material thickness: | 1,0 mm |

| for smaller bending width max: | 2,0 mm |

| Available radii: | 0,2 mm / 0,5 mm / 1,0 mm / 2,0 mm |

| Accuracy: | 0,1 mm / 0,5° |